Structural Steel Products

Competitive Advantages

- Our local project management team has over 50 years experience supplying structural steel projects to the Australian construction industry

- Competitively supplying steel poles and towers to Australia since 2020 in Telecommunications and Electrical projects.

- Our mission to become a market leader in structural steel for Australia

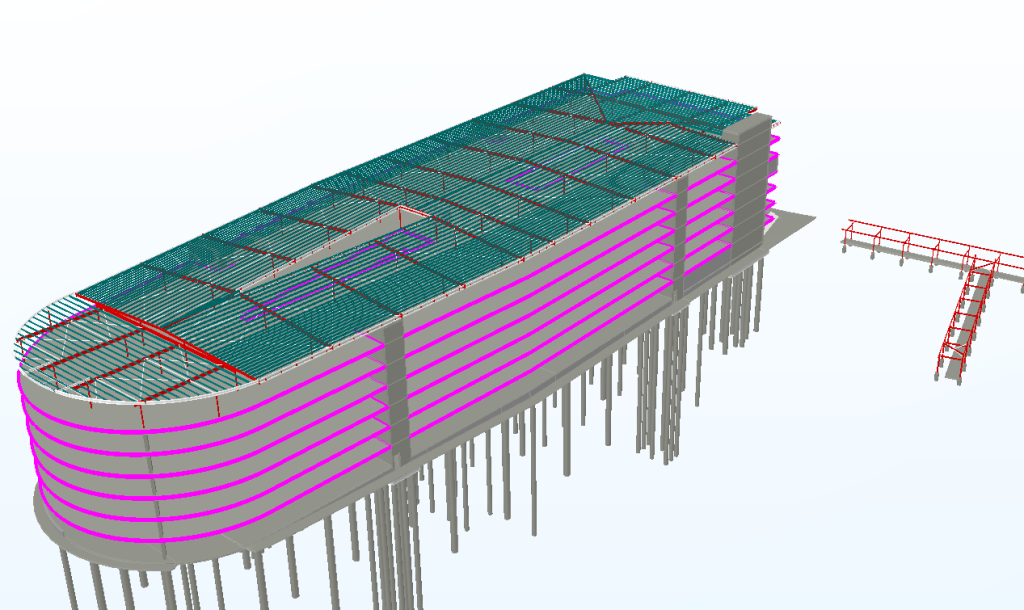

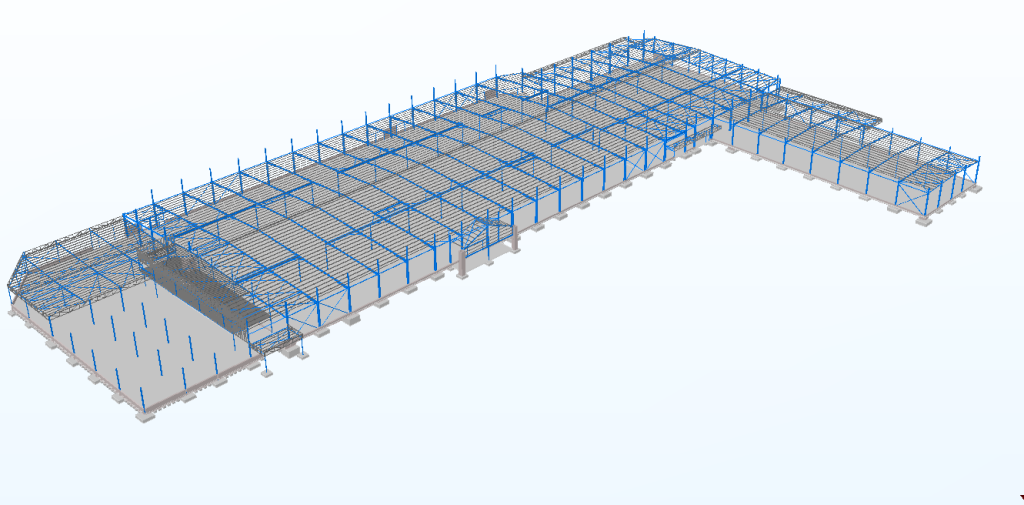

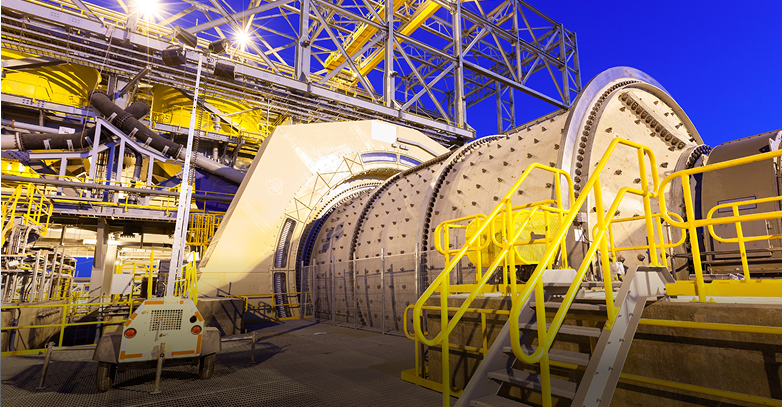

- Design, Fabrication and Installation of Structural Steel Packages upto 8000tons

- Materials, Fabrication and welding in accordance with AS4100, AS5131, AS1554, ISO3834

- Deliver Monopoles, Lattice and Pipe Towers to the Australia Electrical and Telecommunication industry, with both a quality advantage and competitive cost compared to alternative suppliers.

- Australian based drafting and projects managers dedicated to delivering your Structural Steel project from design through to installation.

- Inhouse drafting team, working exclusively with Australian standard connection details and drafting requirements.

- Drafting capacity upto 300tons per week.

- Our capacity to design and optimize steel monopoles, lattice and pipe towers is backed by a seasoned engineering team of 50 members.

- Operating three fabrication facilities with an annual capacity of 82,000 metric tons, we diligently maintain them to consistently meet the strict timelines of all our new project schedules.

- Our logistics team, renowned for their diligence and high efficiency, is well-trained and has streamlined our processes to ensure rapid delivery times.

- We work closely with our clients to optimize project schedules, often surpassing local fabrication times with our delivery schedules.

- Full adherence to Quality Control Regulations (QCR) is a mandatory global project requirement, stemming from our extensive export experience and inherited QA/QC policies from our prior Japanese and Korean partners, a tradition we have upheld since 1996.

- Collaborate with Germany’s HwC (NATA equivalent),

- Vietnam’s exclusive entity authorized by the

- International Institute of Welding (IIW) for international welding personnel certification,providing 3rd party verification.

- Materials and certified welding procedures adhere to Australian Standards, with ISO acquired